|

|

drukomat® plus - the new range

function:

|

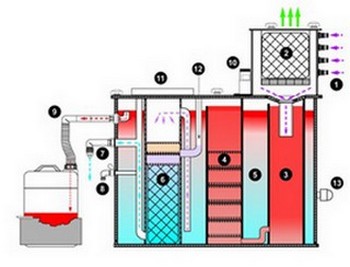

flow diagram:

|

- Condensate feed is possible both under pressure and

pressureless

The condensate is feed from the compressor,or the tank, or the

dryer if possible with pressure.

(4 connections R 1/2´´)

- Chamber for expansions and de-airation with charcoal

filter to exhaust air

This expansion and de-airation chamber assures a chalm surface

in the separator, even if the condensate is fed under pressure.

The activated charcoal filter eleminates the oil from the exhaust air.

- Collecting chamber

Here a first force of gravity separation of oil and water occurs.

- NEW: preko-Filter - selfcleaning

- Setting and floating chamber

- End stage filter

- Water discharge

The remaning oil content of the water discharged is less than

10 mg/ltr. if the equipment is correctly dimensioned. This water can

be discharged directly into the sewers.

- Test valve

The test valve permits very simply to take discharge water samples.

- Oil-collect tank with overflow safe-guard

- Testset

Check-glass and oil-test-paper to control the condensate easily.

(Regular control through the operator)

- Document department

Opersating instructions as weil as the "Check- and Maintanence

Book" are at the fingertips at all times.

- Level- / Filter-control (optional)

a) level-switch with powerless contact

b) complete batery charged unit with signal-light and

contact for remote control.

- Heater (optional)

|

|

|

|

|

|

|

------ www.drukomat.de ------ |

|

|

|

| |